One of the classes I'm taking this semester is called Introduction to the Fashion Industry, and half of the course is field visits to local companies in the garment industry. It's been an eye-opening experience!

This week, we visited

- National Sewing (a contracting company)

- Taylor Stitch (Indie raw jeans and button up shirts company)

- Weston (Julie Weston's designs, sample construction, and wholesaler)

- Holly Hill (boutique shop in San Carlos)

I took a few photographs along the way!

National Sewing was the biggest learning experience for me during our trip out. Nowadays, almost all of our clothing seems to come from Asia, and while I know there are contracting companies (i.e., sewing factories) here in the USA, I had no idea that there are 60-80 of them in the Bay Area alone. Of course, the caveat is that decades ago, there were hundreds of sewing shops, which have closed up as more companies seek cheaper manufacturers abroad.

This is what the contracting company looked like when we first walked in. It's pretty packed with machinery!

You can see some piles of Chubbies shorts being made.

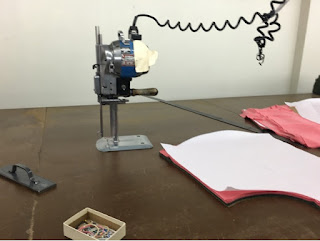

This here is a fabric cutting machine. They can stack up several inches of fabric layers, and cut out garment pieces all at once, in different colours!

In stark contrast to the organized chaos of the contracting company, the next place we visited was Taylor Stitch, an indie clothing shop full of raw denim and very nice button up shirts. I'm thinking I need to head back at some point to get a shirt for Spousal Unit!

Here, we got to learn a bit about the retail experience for independent clothing lines, how important it is to foster a community for small stores like these, and also how critical it is to be familiar with your target market.

The store in the Mission is a very cool space, also!

Look at these gorgeous shirts. Don't you just want to stick your hand in between all of them? I can still feel the crisp cotton. Aw yeah, fibre.

At Taylor Stitch, you can get measured for a custom shirt, which is made in New Jersey. They have an appealing little corner in their shop dedicated to their swatches and all the tools they need to take measurements.

Having covered manufacturing and indie retail, we moved on next to the offices of Weston, formerly known as Weston Wear. Headed by the designer, Julie Weston, the employees at Weston operate a full design house. You might be able to find some Weston designs at large department stores, but also at Anthropologie.

Check out these racks of patterns (you can't see it in this shot, but one section actually was labelled "Anthro"):

Here's a photo of Shawn, taking photos. :P

Along with their fabric, next to their garment sewing area, was this amazing thread cabinet:

And of course, tools modern pattern makers need: a digitizer (left) and plotter (right):

Our last stop during this field trip was at Holly Hill, a small boutique shop in San Carlos, to get a taste of the retail end of the garment industry. The owner and manager of the shop, Holly Hill, explained her purchasing process to stock her store. Much like what we heard at Taylor Stitch, knowing your customer base and building a bit of a community are essential to survival in running a store like this.

Holly Hill boutique is stocked with plenty of gorgeous clothing, and my wallet did not leave unscathed!

Here's a photo of Holly herself, posing for a photo for Shawn, who is hiding behind the calla lilies to the left:

Our field trip days are long and tiring, but extremely informative. When I initially signed up for this course, I was completely clueless about the garment industry. For someone trying to enter it as a career, this is a pretty frustrating state to be in! But just one day of visiting places has taught me a lot about what to expect, and I am definitely looking forward to our next day of visits tomorrow!

Good post. I like your blog. Keep sharing such a informative post.

ReplyDeletenon woven bag making machine in india

The internal combustion wasn't invented until the late nineteenth century and the driving force for machinery in factories, mines and on farms was the steam engine. ... The traction engines could also drive large circular saws, the power being transferred via a large flat belt from the flywheel on the engine. Biscuit machine Belt

ReplyDeleteThis can be done efficiently with the help of high quality of instruments that must be designed with specialized features and standardized quality of raw material. Mullen burst tester

ReplyDelete